Recent Posts

Category

Acceptability Criteria of Printed Circuit Board, what standard do you use?

As a printed circuit board manufacturer, PNC Inc., Nutley, NJ, our criteria of acceptability during the inspection process is determined by IPC–A–600. The scope of this document describes the acceptable and non-conforming conditions of a bare boards either externally or internally during the final inspection process. The inspection criteria is then broken down into three classifications of acceptability, Class I, Class II and Class III. Each class’s acceptance criteria is then again broken down into three areas, target condition, acceptable, and nonconforming for the imperfections in question.

At times there can be a disconnect or confusion between the end-user and the manufacturer in terms of acceptability criteria. Why? Is the PC board manufacturer shipping inferior product, or not interpreting the IPC standard incorrectly? Does the end-user use a standard for acceptability during incoming inspection, such as IPC-6012? These are only a couple of questions why there may be a disconnect in determining the acceptance or nonconformance of a bare rigid board.

The intention of this blog is to help inform and decipher the IPC–A–600 acceptance criteria for a bare printed circuit board. Over the next few months, I will break down imperfections with pictorials, and explanations of the acceptance, or nonconformance for a particular imperfection. I will start with the most common defects seen in the manufacturing process of a PC Board.

Today, I’d like to look at one of the most common occurrences, external annular ring of supported holes. The condition in question is where the drill in the plated through hole appears to be off center in the pad, as seen in figure 1 below. This occurrence happens because of manufacturing tole rance build ups through the process. The two main contributors are Drilling and Primary Imaging.

Figure 1

The combined tolerance between the two processes for most PC Board Manufacturers can be +/- .003 for positional accuracy. Typically most Drilling Machines have a positional accuracy of anywhere from .0005” – .001”, whereas primary imaging photo tool registration can be out as much as .003” due to film stretch or shrinkage. In knowing that there are manufacturing tolerances involved, let’s look at the IPC rule for this condition.

According to IPC-A-600, Acceptability of Printed Circuit Boards, we need to determine the minimum annular ring of the supported hole. This can be found in section 2.10.3 External Annular Ring-Supported Holes, as seen in Figure 2103a, since there is no break out. As you can see the target condition is where the hole is centered within the land.

The ruling criteria can also be found in Table 3-5 Minimum Annular Ring from IPC-6012B. For the holes in question from Figure 1, the inspection process used Class II as their criteria.

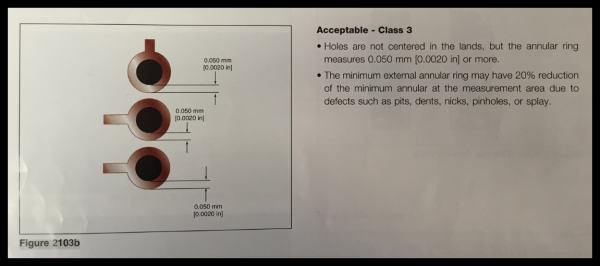

After viewing the customer’s original Gerber data, we find that the annular ring is specified at .009 “. Our findings at the narrowest point of the annular ring measured was .006” on the board. We know that it does not meet the Target condition for Class II per IPC, so we’ll look at the acceptable condition from Figure 2103b.

In this case, Class III is the only acceptable criteria for this condition which states, “Holes not centered in the lands, but the annular ring measures .050 mm or .002” or more. Also during the observation, there were no defects such as pits, dents, nicks, pinholes or Splay, so we do not use the 20% rule for this condition. Knowing that we have more than .002” of annular ring remaining, this condition passes the inspection process per IPC-A-600 section 2.10.3.

I realize to most of you that this is very elementary, and the rule is straight forward. In saying that, we find ourselves defending the IPC rules with individuals whom are unaware of IPC-A-600 and/or IPC-6012 standards. Over the past 20+ years in this business, I have seen great strides in companies having their employees educated and/or certified to IPC standards. I can only hope the trend continues.